FIT WITH CONFIDENCE

A range of reliable push-fit fittings for professional installers.

INSTALLATION INSTRUCTIONS

Compatibility & Jointing

PolyPlumb® & PolyPlumb® Enhanced

Compatible with Polypipe Plumbing & Heating pipe and copper pipe.

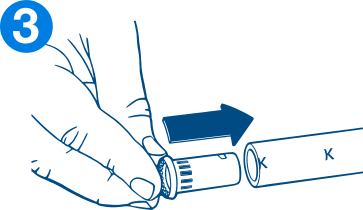

Cut the pipe squarely with a Polypipe pipe cutter using the ‘K’ marks on the pipe as a guide.

These marks help indicate when the pipe has been fully inserted into the fitting.

NB – If jointing copper pipe a rotational pipe cutter should be used. Ensure that all cut ends have a rounded lead in and the cut end is deburred to remove any sharp edges. Never use a hacksaw.

Visually check the pipe for any scratches or abrasions.

If any are found, the pipe should be cut back to a point where there is no damage, as this may compromise the joint integrity.

Fit the In-Cert® Stiffener into the pipe ensuring that it is fully inserted (not required on copper pipe).

Pipe stiffeners are an integral part of the joint when using Polypipe Plumbing & Heating Pipe with either PolyPlumb® fittings or compression fittings.

Polypipe offer other types of pipe stiffener both metal and plastic. However, whilst these are compatible with new PolyPlumb® fittings they do not feature the In-Cert® feedback technology.

Visually check the fitting to ensure that all components are present and that there is no damage or contamination (e.g. plaster, cement or other or site debris).

NB – The presence of contamination can lead to damage of the internal components and may compromise the integrity of the joint.

Lubricants – All Polypipe fittings are supplied with pre-lubricated EPDM O-Rings. If any further lubrication is required only Polypipe silicone lubricant should be used. Substances such as solder flux must not be used.

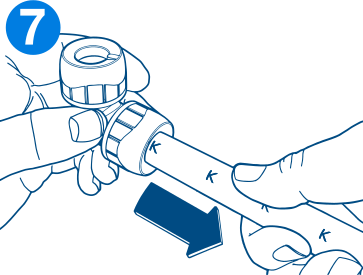

Squarely push the pipe into the fitting ensuring that it is fully inserted by using the ‘K’ marks as reference.

NB – Where the cut has been made elsewhere or if using copper pipe, the insertion depth should be marked on the pipe as below:

Pipe Diameter (mm) 10 15 22 28

Insertion Depth (mm) 22 27 30 35

Gently push and twist the pipe in either direction to activate the In-Cert® Feedback Technology.

The haptic click of the In-Cert® technology gives real confidence the joint has been made; just push the pipe home, twist and you know the jobs done.

A quick tug on the pipe will confirm that the pipe is inserted past the grab ring.

It does not however ensure that the pipe is fully inserted as this can only be confirmed by using the In-Cert® Feedback Technology or depth insertion mark.

Pressure testing should be carried out as follows:

Low pressure test 1bar for 30 minutes

Followed by

High pressure test 18bar for 30 minutes

Do not re-joint.

The joint is single use only, the grab ring MUST NOT BE REUSED.